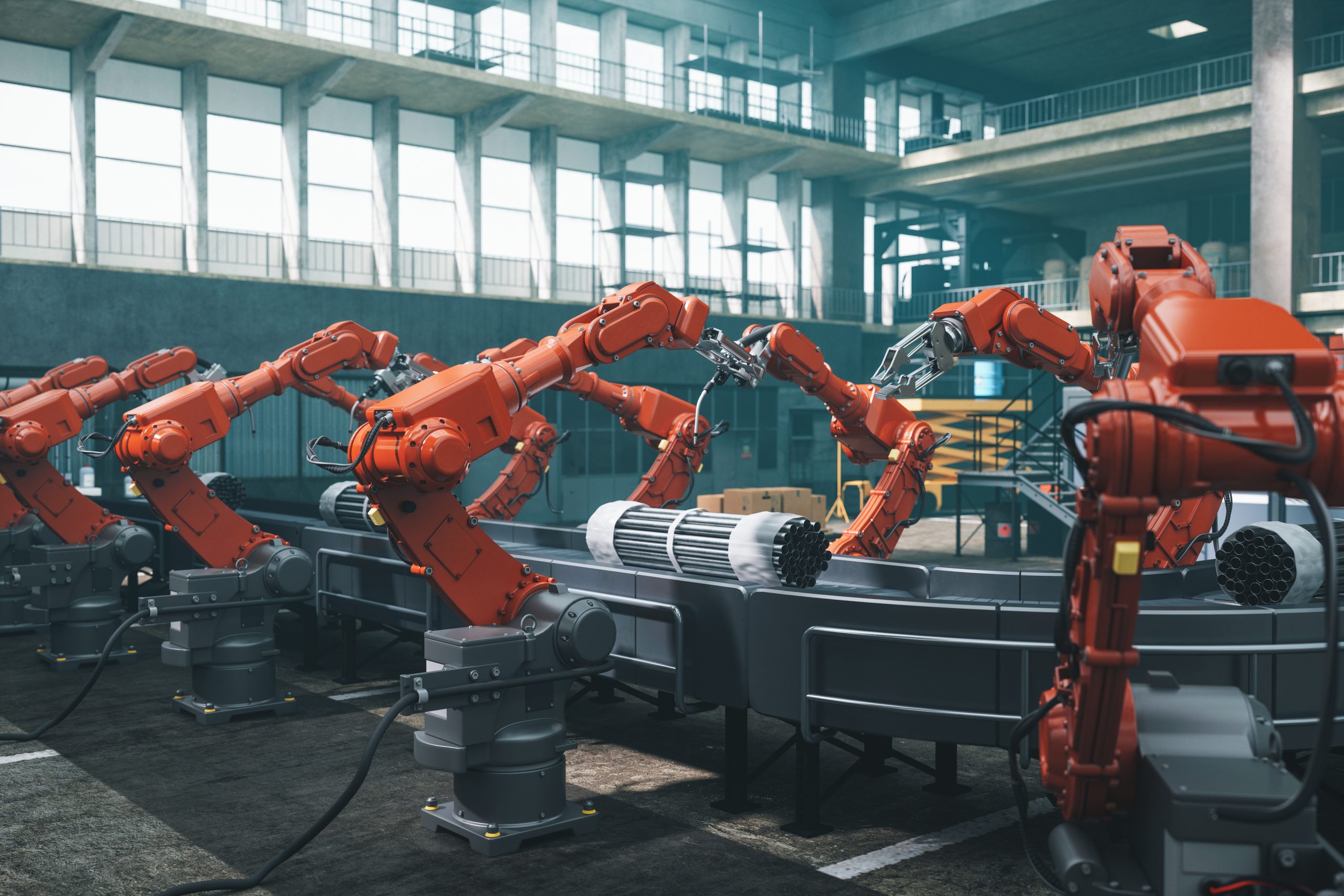

Discover how you can realise untapped automation potential in your production.

Get advice and guidance on robotic solutions and implementation in production. At R-24, you can experience technology targeted to your specific needs, meet others from your industry, and benefit from their experience and know-how.

See a rich variety of technologies to automate virtually any type of factory and end product and meet the professionals who can give you an overview of the possibilities, benefits, and implementation of robots in your production.

Prevent and remove bottlenecks between departments and processes in production so your customers don’t have to wait too long for deliveries. Robotics and cobots can help you and your colleagues shorten lead times.

Prevent overtime by equipping, for example, skilled welders with “little helpers” in the form of welding robots that can do the routine tasks while the welders take care of the complex tasks that require dexterity.

Increase machine utilisation by automating machine tending, such as CNC machines, to free up time and focus – instead of employees being interrupted from their other tasks throughout the day.

Eliminate manual tasks that take a toll on the body. Humans shouldn’t work like machines, and most people can’t stand it in the long run. With the huge innovation in robotics and end-of-arm tooling, more and more tasks such as screwing, polishing, quality control, surface treatment, and packaging can be automated.

Employees can do more value-adding tasks than transporting items from a to b within a company. That’s why warehouse robots and logistics automation with mobile robots and autonomous trucks are becoming more and more popular these days.

Employees at Esbjerg-based Vestfrost Solutions have been spared a lot of noisy forklift traffic, and they no longer have to manually push heavy trolleys between departments.

Three mobile robots now quietly circulate with 80 trolleys that transport raw materials, components and waste between 40 stations at the white goods factory.

This has significantly improved the flow of the factory, as goods are now available before production runs out.

Robotics has thus made a big difference for a company that has been working at full speed during the corona pandemic as a supplier of, among other things, freezers for vaccine storage.

Efficient automation at Danpo creates growth and healthier jobs: A new state-of-the-art production line has geared Danpo to become a major supplier of nuggets in Northern Europe to a global fast food chain.

Together with an automation partner, Danpo designed a fully automated packing centre with robotic palletising and automated guided vehicles (AGVs).

The new line strikes a successful balance between production costs, capacity, volume, deliverability, and working environment.

Less material consumption. Less environmental impact. Less waste at the end customer.

There are gains on all shelves in optimising 8 pieces more

than 20 years old stretch wrapping machines at furniture manufacturer Tvilum. The consumption of stretch film is now 50 – 60 % less when the pre-packed pallets leave the warehouse . Stability and quality of the of the pallets has even better because the film is wrapped even tighter around the the wires on the the pallets.